The drum dryer consumes 1.2 to 1.4 kg of steam to evaporate 1 kg of moisture. This thermal efficiency is much better than a spray dryer, making it an energy saving dryer.

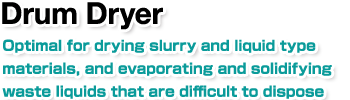

Operation is continuous, and unattended operation is also available.

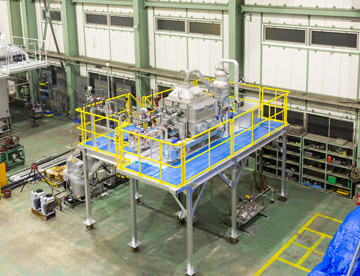

The drum dryer structure is simple, taking up less installation space than other dryers such as the hot air type, and maintenance is also easy. As a result, this dryer is used for a wide range of drying, from products to waste materials.

■Drying Method and Heat Source

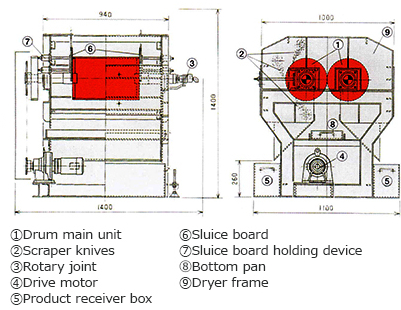

In the drum dryer, materials such as liquid, paste or dewatered cake adhere thinly to the surface of the rotating heat drum and are dried for about 15 to 60 seconds per rotation. The materials are scraped off into powder, flakes or film by scraper knives, before being collected.

Steam is used as the heat source, at a pressure of 2 to 10 kg/cm2G (0.² to 1 MPa).

- 1. Dries dewatered cake or aqueous solution, slurry or sludge type materials, etc., directly into powder, flakes or film.

- 2. High thermal efficiency. Steam consumption is only one-half to one-third the consumption of hot air dryers.

- 3. Short drying time minimizes the effect of heat on the product.

- 4. Smaller installation area than hot air dryers.

- 5. Continuous operation type, and unattended operation is also available.

- 6. Very short start-up time until operation starts, even in winter.

■Production materials

Starches, food, traditional Chinese medicines, pharmaceuticals, ceramics, pottery raw materials, chemicals, etc.

■Sludge

Sludge at sewage or human waste processing plants; active sludge at food, oil or chemical plants, etc.; processed sludge at printing plants, etc.

■Wastewater

Wastewater from fume cleaning of exhaust gas at plants, power stations or incinerators for urban garbage; wastewater from treatment at industrial waste disposal plants, hospitals or nuclear power plants; wastewater from treatment at plating plants or reverse osmosis plants; or wastewater from other dewatering or filtration processes, etc.

![]()

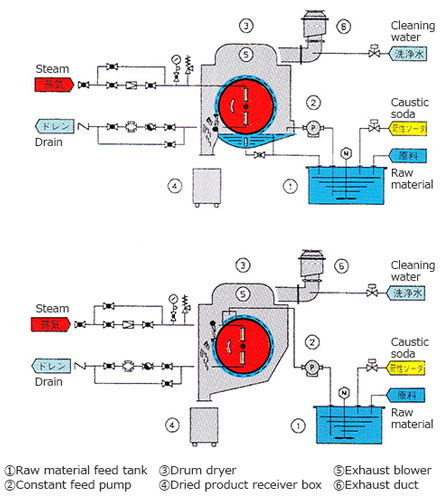

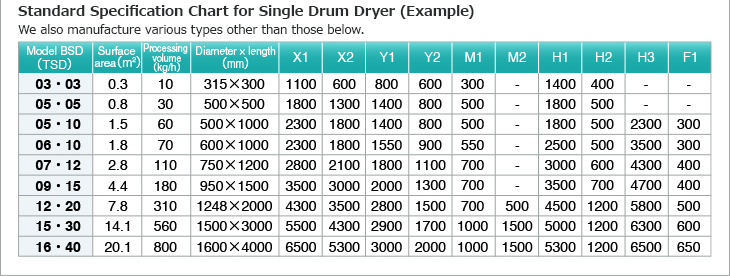

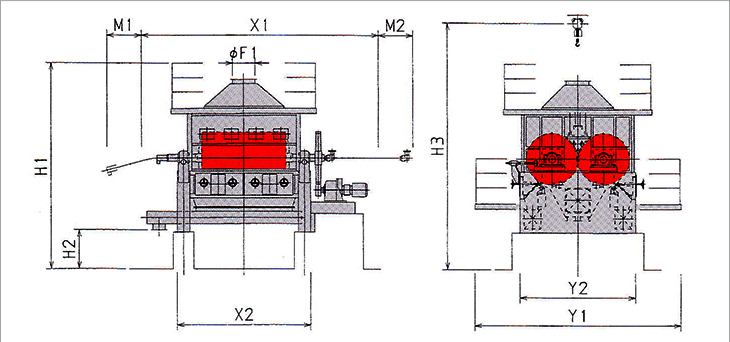

Bottom Feed Type (BSD)

The bottom of the heat drum is inserted directly into the raw liquid tank, and the raw liquid adheres to the drum surface. The raw liquid is dried by the rotating drum and scraped off by the scraper knives. In some cases, a swing type agitator is installed to prevent sedimentation in the raw liquid tank.

Top Feed Type (TSD)

The raw liquid tank is installed at the top of the heat drum, and the raw liquid is fed onto the drum. Used for drying materials such as ceramics or pottery raw materials that have a high specific gravity.

![]()

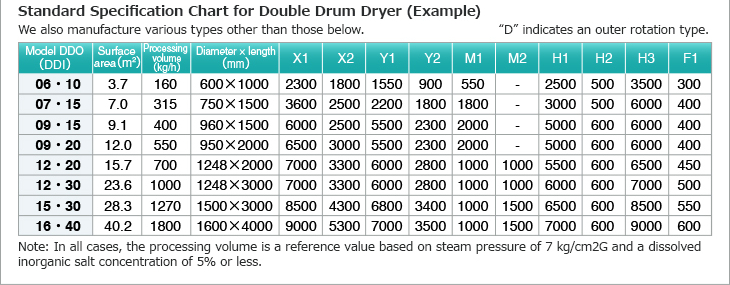

Inner Rotation Type (DDI)

(Two drums rotate to the inner side)

The raw material is fed above the two heat drums and preheated on the drum top surfaces, and adheres to the surfaces with a thickness corresponding to the gap between the inner-rotating drums. The raw material is dried by the rotating drums and scraped off by the scraper knives. This type is suitable for drying relatively viscous dewatered cake or sludge.

Outer Rotation Type (DDO)

(Two drums rotate to the outer side)

The raw material is fed above the two heat drums and pre-dried on the drum top surfaces, and the raw material adheres to the surfaces of the outer-rotating drums and is dried. Because preliminary concentration is performed on the drum top surfaces, the drying speed per unit of drying surface area is 1.5 to 2 times faster than the BSD type. The outer-rotating motion eliminates problems such as salt or other crystalline solids jamming the drums, and no surface pressure is applied between the drums by the raw material, which extends the service life of the drum surfaces and bearings. This type is suitable for drying materials such as dissolved salt.

A test machine is available, so please feel free to use.

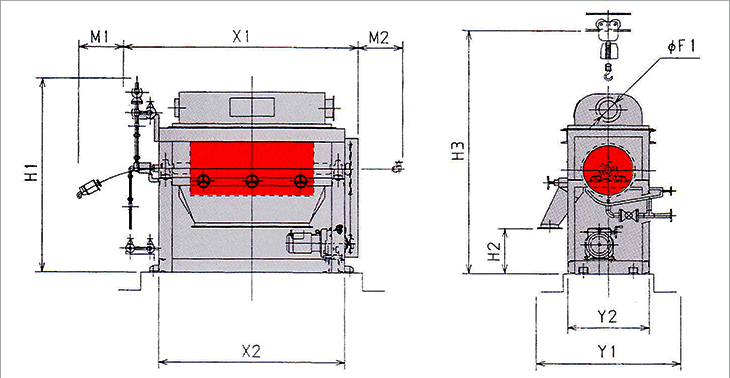

Model: BSD DDO DDI 03/05-SBModel combining single and double types

Processing capacity: 15 to 20 kg/h

Steam pressure: 2 to 7 kg/cm²G (0.2 to 0.7 MPa)

Effective surface area: Single type 0.5 m2, double type 1.0 m2

Please prepare a sample of 18 to 20 liters.

If you would like a test, we will send you the "Sample Test Application". Please fill in the application and send us the sample.