Based on this extensive experience, we aim to progress even further by continuing to take on the challenge of developing easy-to-use ovens that pass the highest quality standards required by the metal printing market.

Providing energy-saving, antipollution and environmental countermeasures, the direct combustion deodorizing/indirect heat recovery oven incorporates a waste heat recovery system and exhaust processing system based on a fume incinerator. The oven fully satisfies the various conditions for ink and paint that are required in the coating process to form an attractive and strong coated surface.

The exhaust gas from the oven contains a large amount of volatile solvents. This gas is fed to the fume incinerator (direct combustion deodorizer) for combustion and deodorization.

This exhaust gas passes through a secondary heat exchanger (waste heat recovery) and is heated in advance to a high temperature of 300°C or higher before being sent into the fume incinerator.

This ensures the complete combustion of resin compounds that are normally difficult to burn in the fume incinerator. The volatile solvents in the exhaust gas are also utilized as a heat source.

The hot air sent inside the oven consists of the hot combustion gas after deodorization and air from outside that have passed through the primary heat exchanger and been heated indirectly.

Therefore, the hot air sent inside the oven does not contain NOx (nitrogen oxide).

The humidity and oxygen concentration in the oven is kept to the same condition as the outside air. This produces a high-quality coating with excellent hardness and gloss.

The temperature of the exhaust gas from the oven is normally about 100°C to 120°C.

The exhaust gas also contains a large amount of volatile gas.

A double duct structure is used where the exhaust duct of the oven passes inside the combustion gas duct after deodorization, for the dual objectives of preventing fume adherence and recovering waste heat after deodorization.

The temperature of the exhaust gas that passes through the double ducts is about 200°C. When a direct combustion deodorization method is used, a large amount of fuel is required because deodorizing is performed at a high temperature of about 800°C.

For this reason, a secondary heat exchanger is used to recover waste heat after deodorization and raise the exhaust gas temperature, thus reducing fuel consumption.

The exhaust gas is heated here to 300°C or higher before being sent to the fume incinerator in an energy-saving flow.

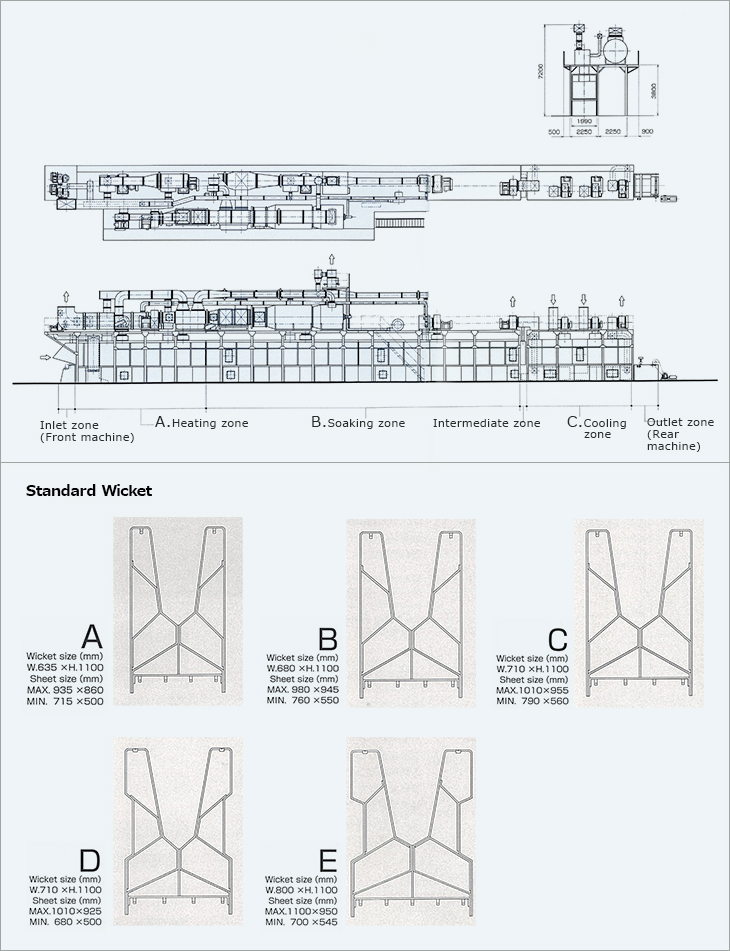

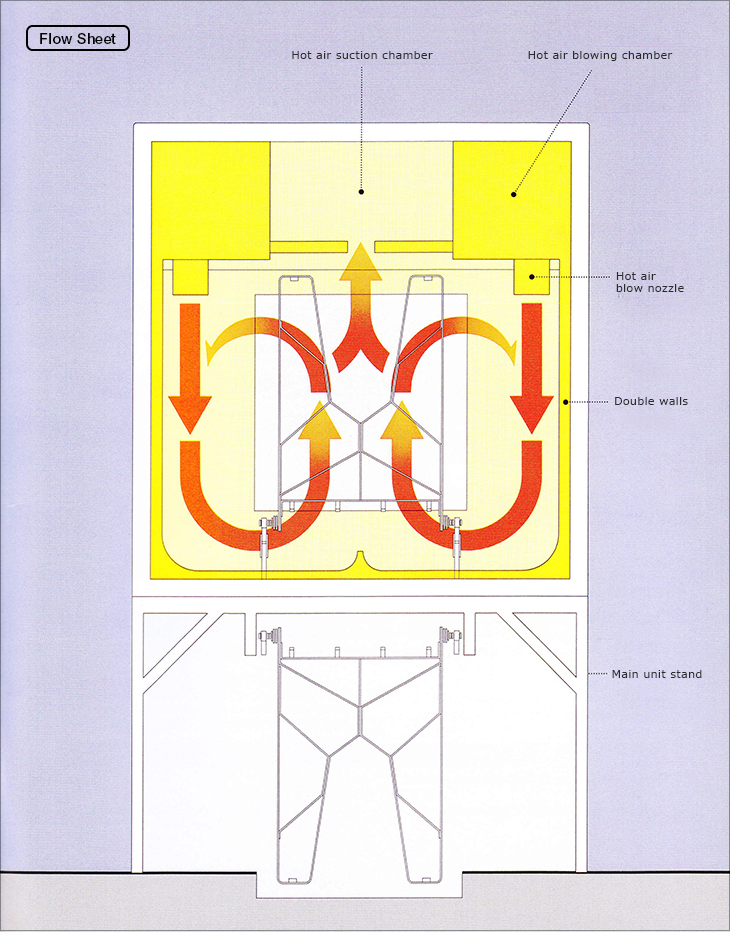

The hot airflow from the hot air blow nozzles on the left and right, the hot airflow between the double walls, and the center suction effect make a swirling airflow form on the left and right inside the furnace.

This airflow creates a fine, turbulent flow between the metal boards to make the contact of the hot air on the board surface even and perform the ideal convection flow heating.

The swirling airflow bakes printed surfaces or painted surfaces evenly with no irregularities to guarantee a high-quality finish.

The hot airflow volume and temperature adjustments required for production conditions such as paint type, metal board material, thickness, dimensions and speed can be performed accurately through the combination of the fume incinerator, hot air blow chamber sensors in each zone, controllers, and automatic dampers.

The forced exhaust by the exhaust port at the oven inlet seals the heating zone inlet to prevent odors and hot air from leaking outside. A sealed zone of about 500 mm is provided between the soaking zone and cooling zone for forced exhaust. This prevents mutual interference between the soaking zone and cooling zone, whose temperatures vary greatly.

When the hot air passes between the double walls of the furnace, the wall surface retains a high temperature to prevent fume adherence. In addition, the swirling airflow is straightened.

The flow volume and flow direction of the hot air blow nozzles can be adjusted to prevent the metal boards from flapping. Therefore, fluttering does not occur.

The air cylinder automatically adjusts the tension of the wicket conveyor chain.

The automatic lubricator supplies an extremely small amount of oil to lubricate the chain. This prevents all problems related to the chain.

The wide chain enables smooth movement of the wicket in the front machine and rear machine.

The rail is made of S-45C hardened steel for minimal wearing, and the airflow speed inside the furnace is slow, so worn particles are not blown up.

The wicket is made of steel equivalent to JIS-10C with a nickel-plated finish for antirust performance and easy cleaning of adhered tar.

There is maintenance space on both sides of the wicket inside the furnace. This makes inspection and cleaning easy without removing the wicket. It also means less work for operators to ensure that the furnace interior is safe and clean.

The main unit frame and side walls have an integrated structure to enable installation in a short time.