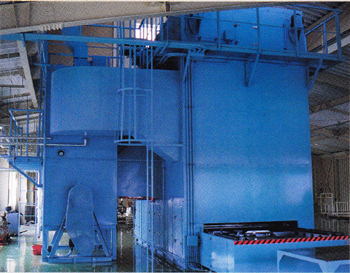

The up-down dryer is a unique and efficient dryer.

The materials to be dried are placed on a tray and the tray is moved up and down automatically. At this time, hot air is applied effectively to the tray surface to dry the materials efficiently.

The movement of the tray in the up-down dryer has been automated to save labor.

The materials to be dried are placed on a tray and the tray is moved up and down automatically. At this time, hot air is applied effectively to the tray surface to dry the materials efficiently.

The movement of the tray in the up-down dryer has been automated to save labor.

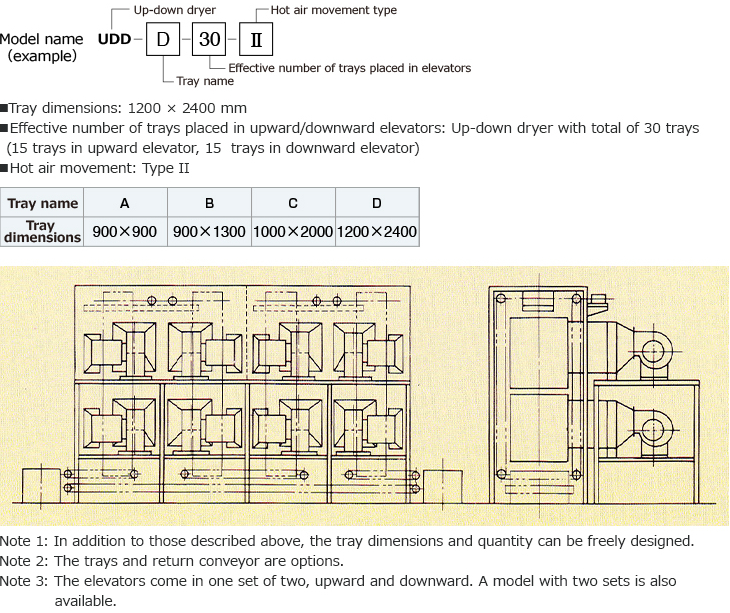

- 1. Suitable for a wide range of material types, including molded parts and board shaped materials.

- 2. Hot air flows over the top and bottom surfaces from the left and right of the tray to reduce drying unevenness.

- 3. The drying time is shorter than other parallel flow type dryers.

- 4. The desired drying conditions (temperature, humidity, airflow speed) can be selected.

- 5. The automated system allows the tray dimensions to be increased.

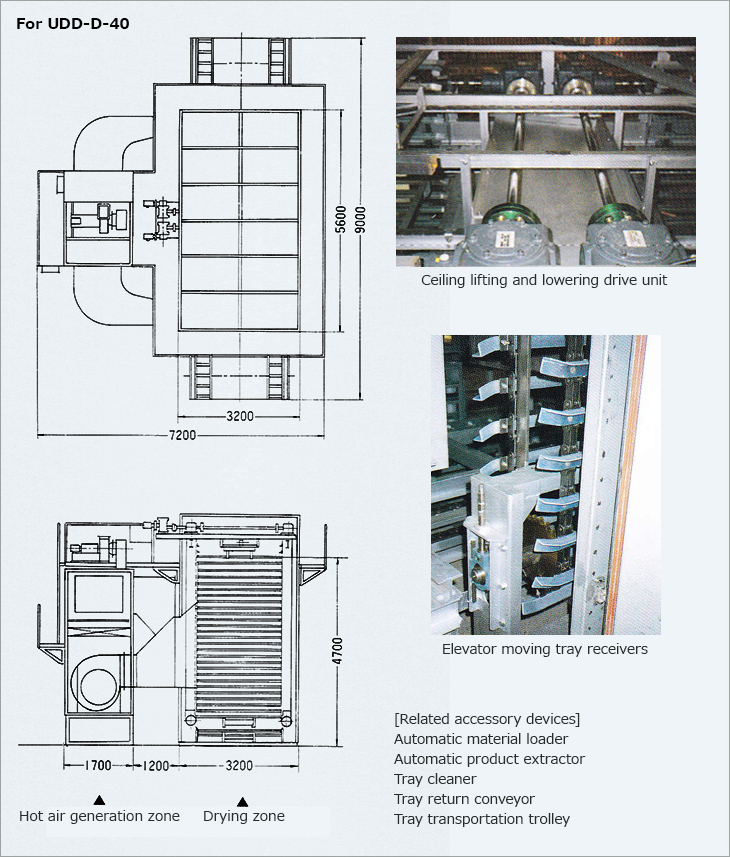

- 6. The three-dimensional structure reduces the required installation area.

- 7. Innovative and reliable ideas help make work more efficient.

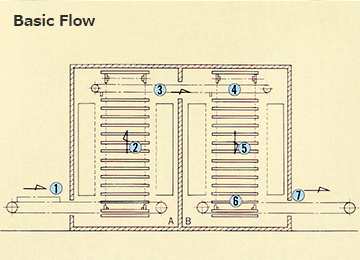

- (1) The materials are placed on the tray and the tray is placed on the inlet feed conveyor.

- (2) The tray is moved to the bottom of the upward elevator by the inlet feed conveyor.

- (3) The elevator raises the tray intermittently, stage by stage, until it reaches the top.

- (4) The horizontal movement conveyor moves the tray to the top of the downward elevator.

- (5) The downward elevator lowers the tray intermittently, stage by stage.

- (6) When the elevator reaches the bottom, the outlet extraction conveyor moves the tray to the extraction port.

- (7) Generally, this tray is moved outside by using a device such as a trolley or conveyor. The tray can also be returned by using the conveyor at the bottom of the main unit.

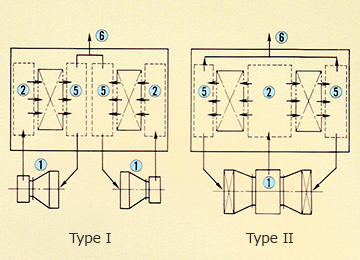

- (1) The air blower and heat source device generate the hot air. (Set to the specified temperature by the automatic temperature adjuster.)

- (2) The hot air enters via the blow ducts and passes in a parallel flow over the top and bottom surfaces of the tray in the upward elevator to effectively heat and dry the materials.

- (3) Similarly, the materials are effectively heated and dried when the tray is on the downward elevator.

- (4) The hot air is blown from the left side of the tray when moving upward and from the right side of the tray when moving downward to shorten the drying time and reduce drying unevenness.

- (5) After passing over the material surface, the air is sucked into the suction ducts, becomes moist, and its temperature is lowered.

- (6) Some of the moist air is discharged outside by the air blower.

- (7) Most of the air is returned to the main air blower as recirculated air, where it is reheated together with fresh air to the specified temperature by the heat source device, and the air is then reused.

■Formed materials ■Board shaped materials ■Clumped materials ■Sludge materials ■Other materials loadable onto a tray