In the finned tube heater, strip-shaped fins are wrapped in a spiral around the surface of steel pipes to enlarge the heat dissipation surface area, and these components are enclosed by a casing. A heating medium such as steam, oil or hot water is used.

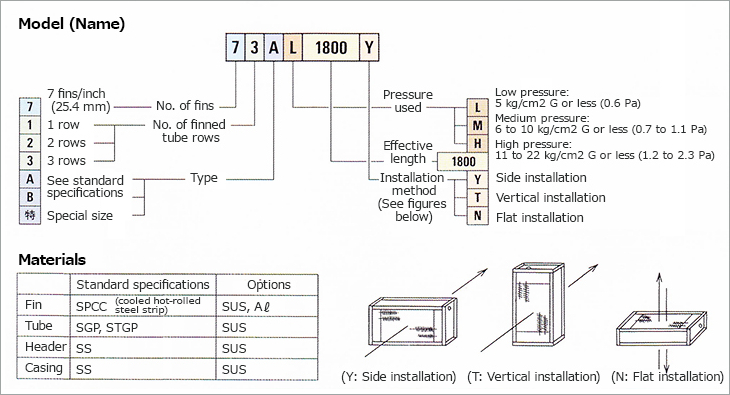

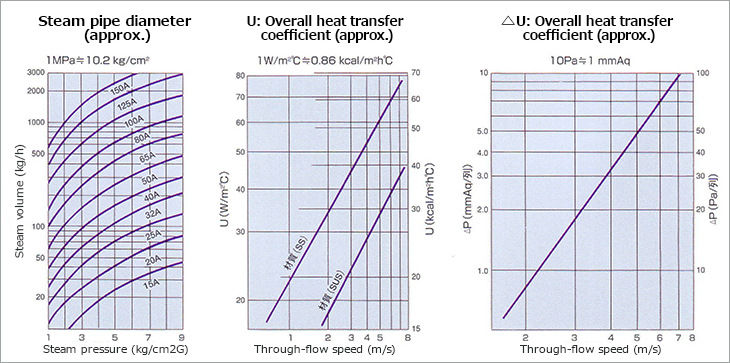

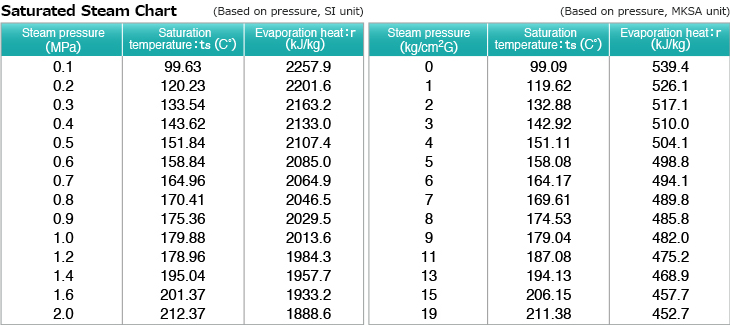

Low pressure, medium pressure and high pressure types of finned tube heater are available, which differ according to the steam pressure that is used.

Combination in parallel or series is possible according to the airflow volume and required heat amount. This device can also be used as a cooler when cold water is used as the heating medium.

Low pressure, medium pressure and high pressure types of finned tube heater are available, which differ according to the steam pressure that is used.

Combination in parallel or series is possible according to the airflow volume and required heat amount. This device can also be used as a cooler when cold water is used as the heating medium.

2. Materials can be selected according to the specifications

3. Heaters can be combined according to the specifications

4. A combination type, therefore replacement of individual sections is possible

5. An ink line method is used, ensuring high heat transfer efficiency

6. Combinations can be selected according to the objective, from low pressure to high pressure

7. Lightweight, sturdy and easy to handle

2. Heater for waste heat recovery

3. Air heater for factories, etc.

4. Cooler for cooling

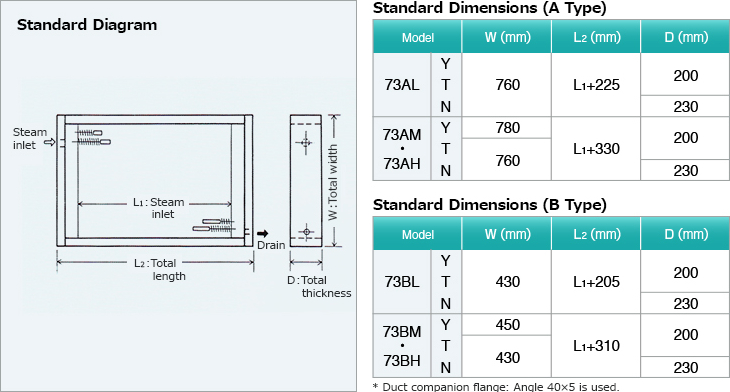

Note 1: The heat transfer area of the 72 type is 66% of the 73 type. The dimensions are the same in both types.

Note 2: The heat transfer area of the 71 type is 34% of the 73 type. The dimensions are the same in both types.

Note 3: We also manufacture types with an effective length other than those above.

Note 4: We also manufacture special types.

Band dryer, rotary dryer, etc.

■Waste drying/incineration systems and related plants

Vortex dryer/incinerator, fluidized bed incinerator, others

■Automated/labor-saving systems

■Accessory devices,Heaters, heat exchangers, deodorizing devices. dust collectors, etc.