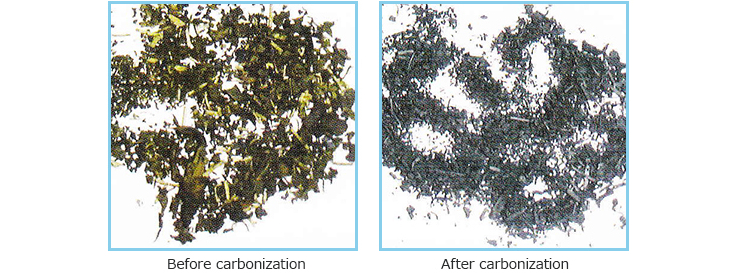

The external heat type carbonizer is the most effective machine for carbonizing organic waste. The resulting high-quality carbonized matter is useful for applications such as enriching agricultural soil.

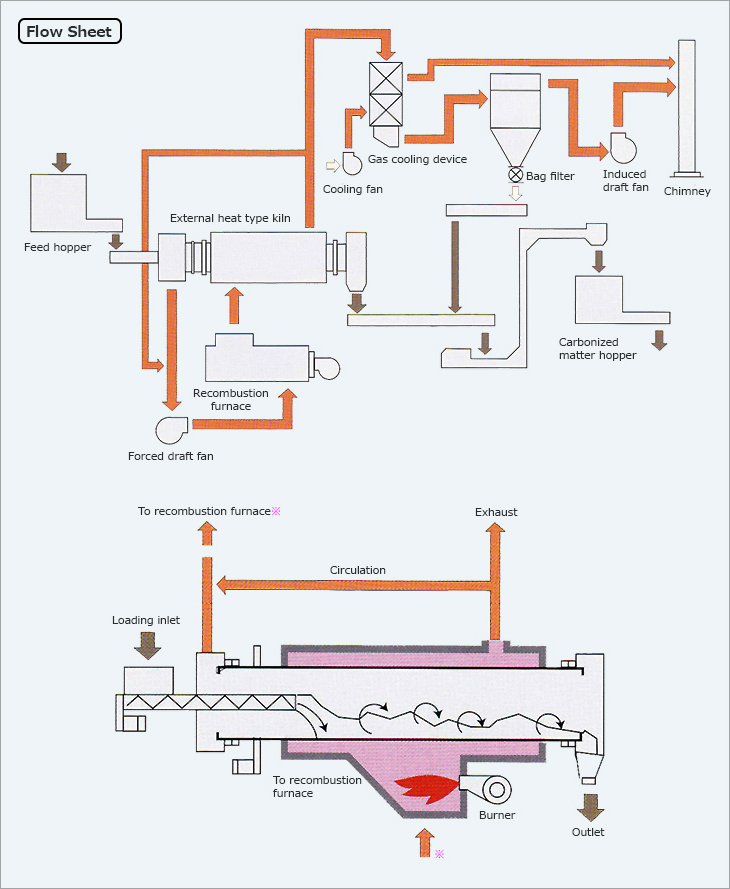

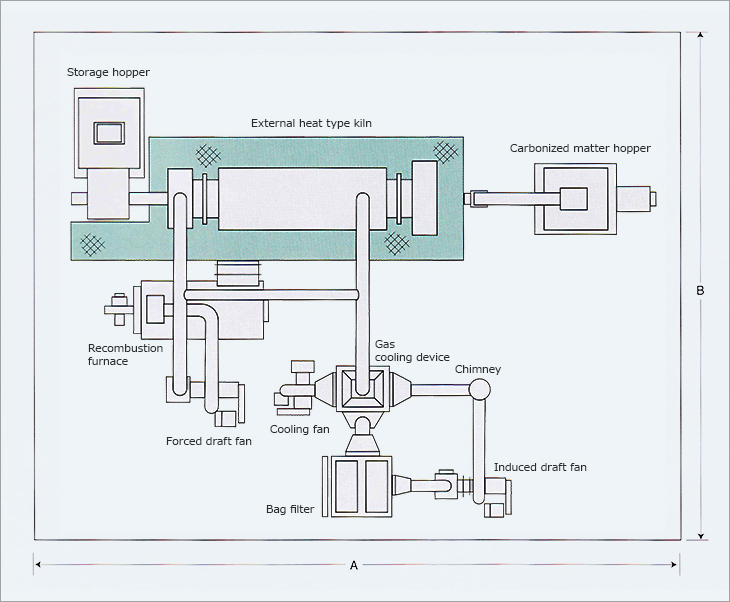

The carbonizer structure is simple. Hot air of 500 to 800℃ is fed into the casing to transfer external heat to the kiln main unit.

The raw materials in the carbonizer are carbonized by the indirectly-obtained heat and then discharged from the outlet as carbonized matter.

The inert gases generated during carbonization are fed into the recombustion furnace for reuse as a heat source. At this time, some of the harmless air is discharged into the atmosphere.

The carbonizer structure is simple. Hot air of 500 to 800℃ is fed into the casing to transfer external heat to the kiln main unit.

The raw materials in the carbonizer are carbonized by the indirectly-obtained heat and then discharged from the outlet as carbonized matter.

The inert gases generated during carbonization are fed into the recombustion furnace for reuse as a heat source. At this time, some of the harmless air is discharged into the atmosphere.