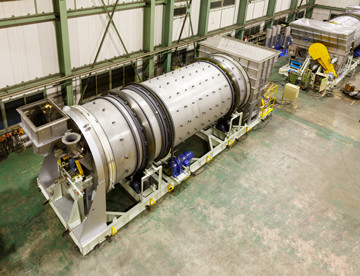

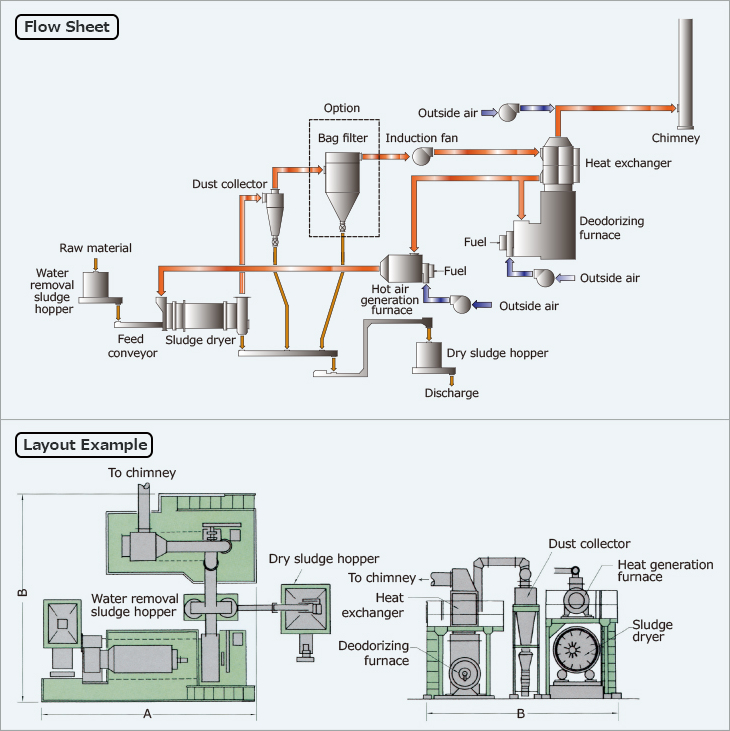

The rotary dryer with agitator is optimal for drying viscous and adhesive materials such as sewage sludge, human waste sludge and active sludge. This dryer has a relatively simple structure and high drying capacity.

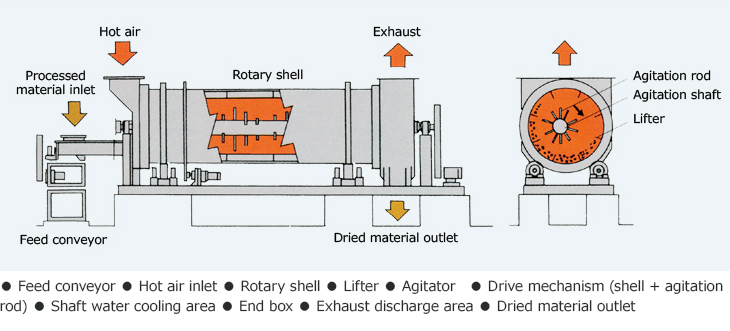

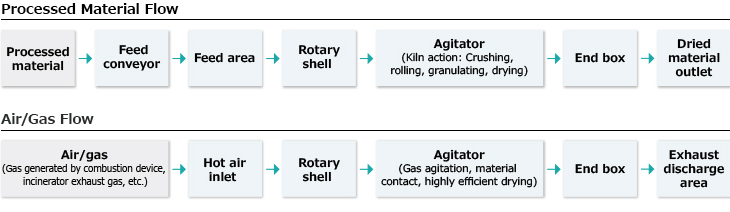

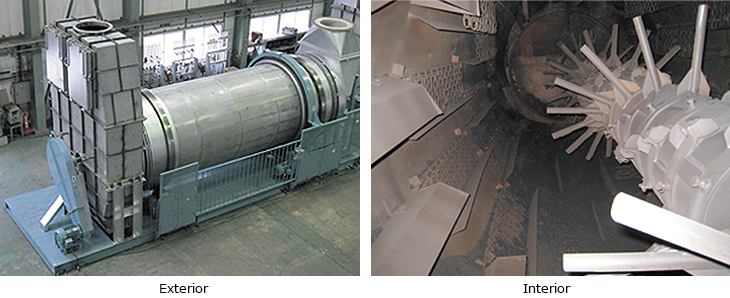

The rotary dryer with agitator is equipped with an agitation mechanism comprised of an agitation shaft and agitation rod inside the rotary cylinder (shell). The scooped-up materials are repeatedly crushed and dispersed by the agitation mechanism to improve the contact with the hot air and make drying more efficient.

Patented in the USA, EU, and 5 other countries.

The rotary dryer with agitator is equipped with an agitation mechanism comprised of an agitation shaft and agitation rod inside the rotary cylinder (shell). The scooped-up materials are repeatedly crushed and dispersed by the agitation mechanism to improve the contact with the hot air and make drying more efficient.

Patented in the USA, EU, and 5 other countries.

- 1. Fast drying speed.

- 2. Uses high temperature gas for excellent thermal efficiency.

- 3. A low volume of gas is used, therefore the exhaust gas processors (dust collector, deodorizer) are small.

- 4. Can be used with materials that are viscous, adhesive, or contain large amounts of moisture.

- 5. Highly adaptive to changes in the sludge.

- 6. Generally, produces dried materials with a granule diameter of about 1 to 5 mm.

Used for applications such as the following.

Sewage sludge, human waste sludge, food residue, resins