The fluidized bed band dryer is a highly efficient dryer that causes minimal particulate fracture and can be used even for materials with high moisture content, mixed particles and irregular shapes.

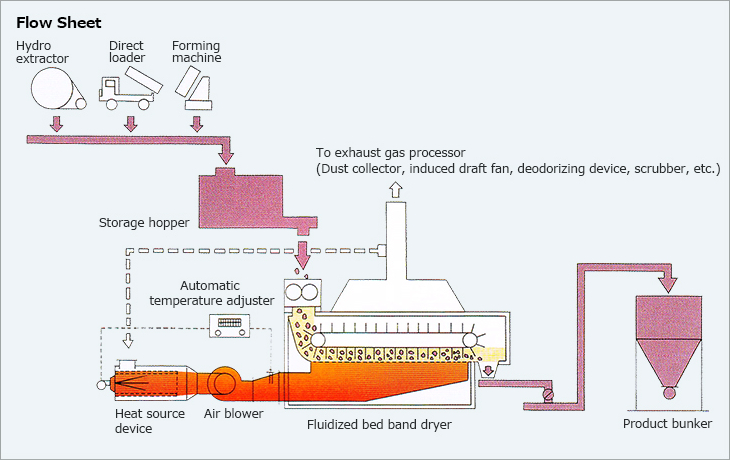

In this dryer, a band conveyor is positioned on a fluidized bed to convey the materials, and hot air is blown from the bed to apply a fluidized bed airflow and through-flow to the materials.

This spreads the materials vertically and constantly renews the evaporation surface area, which makes drying more efficient.

In this dryer, a band conveyor is positioned on a fluidized bed to convey the materials, and hot air is blown from the bed to apply a fluidized bed airflow and through-flow to the materials.

This spreads the materials vertically and constantly renews the evaporation surface area, which makes drying more efficient.

The fluidized bed band dryer has the benefits of both a band dryer and a fluidized bed dryer.

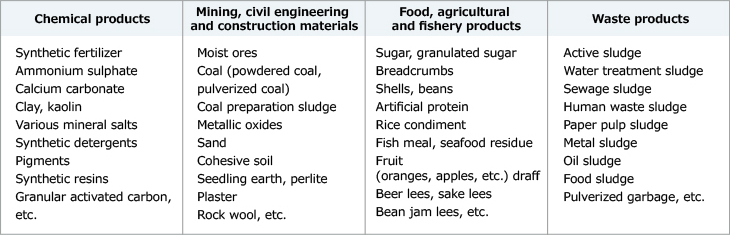

- 1. Wide range of applications

In addition all kinds of particulate materials, this dryer can be used for materials with high moisture content, large mixed particles and irregular shapes that cannot be processed with a normal fluidized bed dryer, and it also operates with a low amount of particulate fracture. - 2. Incredibly fast drying speed

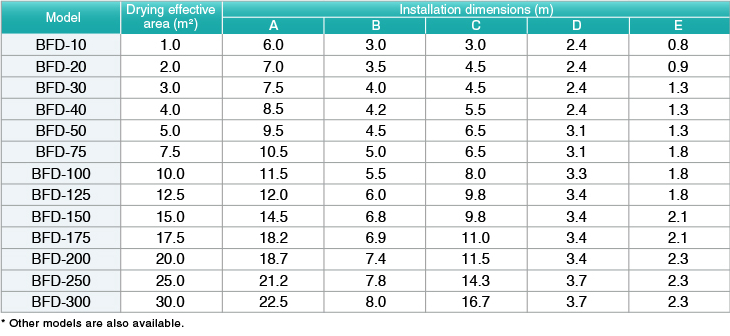

The evaporated moisture per fluid bed effective area is 100 to 400 kg/m²·h. - 3. High heat capacity coefficient

The system can be kept compact even when using low temperature hot air. - 4. Low dusting

The dusting amount is low because the airflow speed inside the machine is slow. - 5. Usable with any heat source

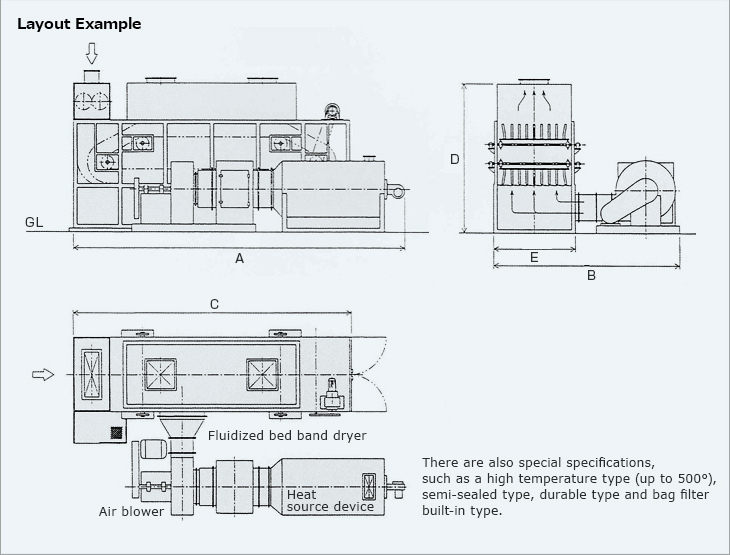

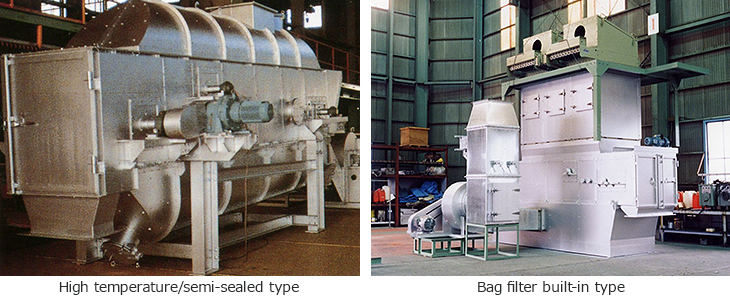

Usable with any heat source, such as steam, gas, heavy oil, kerosene, electricity or exhaust gas. - 6. Dryers available in any size, from compact to large

Because the action of the conveyor rod (rake) inside the machine does not generate the blow-by phenomenon, large machines can be easily produced. - 7. Easy operation and maintenance

The system is simple, enabling easy operation and inspection. - 8. Deodorizing devices sometimes unnecessary

Because operation is at low temperature, odor generation is low, eliminating the need for deodorizing devices in some cases.

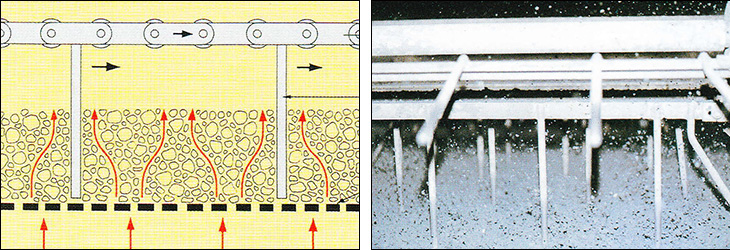

Why is the drying speed fast?

The figure shows an enlarged view of the center part. When hot air passes through the materials, the hot air is applied to all the surfaces of the materials, which makes the drying speed incredibly fast.

The materials are also agitated by the movement of the conveyor rods (rakes). This spreads the materials vertically and constantly renews the evaporation surface, resulting in fast drying.

* A test machine is available, so please feel free to use.