The band dryer is the typical continuous convection heat transfer type of dryer, which has been improved and modified over many years.

This is a hot air type of dryer, where the materials are placed on a band conveyor (steel or perforated plate, etc.) and are dried by hot air as they move through the drying chamber.

In general, the band dryer forcibly passes hot air through the gaps in the material layers to dry the material.

This is a hot air type of dryer, where the materials are placed on a band conveyor (steel or perforated plate, etc.) and are dried by hot air as they move through the drying chamber.

In general, the band dryer forcibly passes hot air through the gaps in the material layers to dry the material.

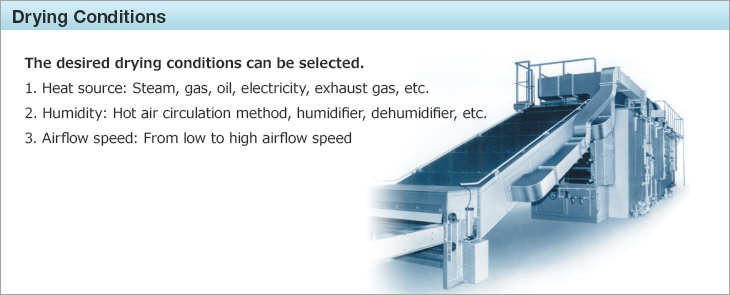

Conditions such as the temperature and airflow speed can be freely and accurately controlled to obtain a high quality dry product.

- 1. The temperature, humidity and airflow speed can be easily set and controlled for each zone according to the progress of drying. (Zone control)

- 2. The drying time can be freely adjusted for consistent heat progression, which produces uniform products with minimal drying unevenness.

- 3. Materials are dried while stationary, which greatly minimizes damage and dust scattering.

- 4. In particular, this dryer allows the granulating and shaping of sludge or irregularly shaped materials. Also appropriate for adhesive or thixotropic materials.

- 5. An (automatic) washing device can be set on the conveyor to make cleaning easy and prevent contamination while maintaining excellent sanitation.

- 6. Usable in a wide range of temperatures, from low temperature (humid air) to high temperature.

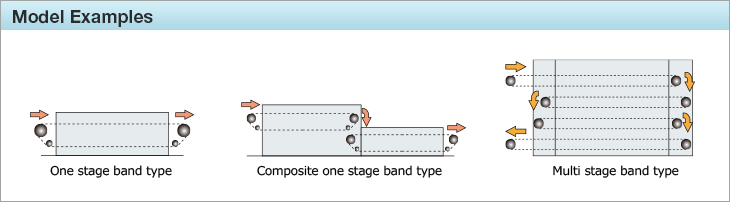

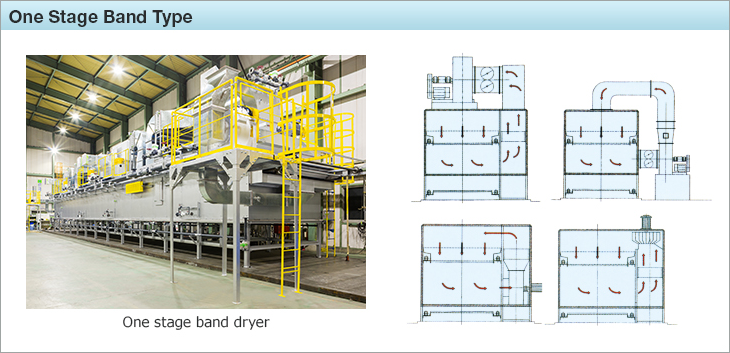

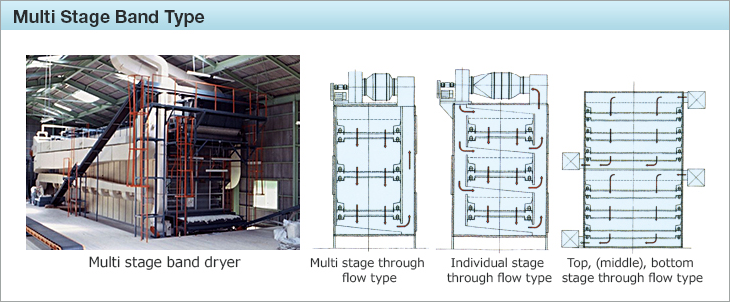

- 7. Various models are available (from one stage to multiple stages) for compatibility with both low and high volumes.

A wide range of materials can be dried.

- 1. Granular food (crackers, snacks, etc.), instant noodles, agricultural produce, chemical products, pods,beans, pigments, dyes, resins, fertilizers, etc.

- 2. Regularly shaped construction materials (boards, rock wool boards, calcium silicate boards, plywood boards, etc.); also IC boards, automobile parts, electrical parts, mechanical parts, etc.

- 3. Thixotropic materials

- 4. Fibrous materials

- 5. Adhesive or cohesive materials

- 6. Other materials such as irregularly shaped materials or filtered sludge cake can be used after applying a forming machine or granulator.

Also usable for heat treatment such as sterilization, glazing or curing.

![Airflow Methods.The airflow method can be selected from various types.The through flow and parallel flow methods are mainly used. Through flow method.Downward airflow.Upward airflow.Upward and downward airflow.In the through flow method, because the airflow speed between particles becomes faster even when the flow speed within the machine is low, a high heat capacity coefficient (ha) can be obtained.[ha = 700 to 2000 kcal/m3h•°C].Drying curve.Moisture content [%], temperature [°C].Airflow speed [m/s].Time [h].Blowing temperature.Airflow speed.Critical moisture content.Moisture content.Material temperature](images/content_img_03.jpg)

■Used for applications such as the following.

Pod drying, various chemical products (carbon fiber)

Various food products (vegetables, cashew nuts, ramen, rice crackers, powdered soup, etc.)

Resin/rubber, etc.